An innovative industrial partnership, wear2wear, is dedicated to high quality and sustainable clothing. Five European companies representing each phase of the recycling process, have come together to develop cutting-edge production systems that will turn textile fibers from used clothing into new functional fabrics.

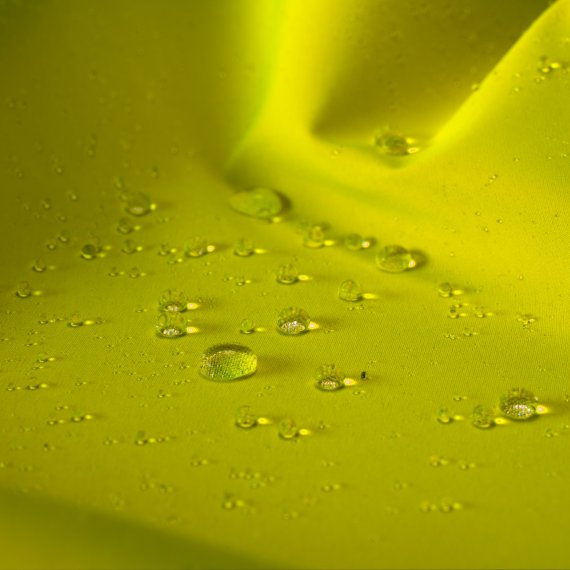

Dedicated to sustainability, the wear2wear concept will recycle textile fibers from used garments to produce new functional fabric. Depending on the final end use, the recycled fabrics will also meet strict waterproofing, breathability, protection and comfort requirements. To ensure that the raw material cycle comes full circle, these textiles can be recycled again when the reach the end of their service life, resulting in no waste.

The five European partner companies in the wear2wear cooperation cover the entire recycling circle. Heinrich Glaeser Nachfolger GmbH is a German fibre and yarn producer and the “recycler” in the loop, collecting garments to be recycled. Märkische Faser GmbH is the “upcycler” and fibre manufacturer. These have now been joined by two further companies: Carl Weiske GmbH & Co, which develops polymers, fibers, yarns, chemical additives and textile systems, and TWD Fibres GmbH (D), a fully integrated filament yarn producer covering the entire range of polyester and polyamide 6.6 continuous filament yarns.

The innovative Swiss company Schoeller Textil AG is responsible for textile production and manufactures sustainable, high-tech fabrics with maximum clothing comfort. The matching climate-neutral and similarly 100 percent recyclable, PTFE and PFC free membrane as well as recycled outer materials and linings are supplied by Sympatex Technologies, the ecological alternative among the textile function specialists. DutchSpirit is a Dutch company dedicated to environment-friendly clothing since 2010, with the mission to significantly increase the awareness for sustainable clothing and provide circular clothing in the corporate and workwear segment. Dutch Spirit is the initiator for the development of the Inspire products and brainchild for the wear2wear concept, with further brands joining.

At Schoeller Textil, the recyclable, functional fabrics from the wear2wear concept belong to the Inspire fabric group. These are high-quality protective workwear fabrics made of 100 percent polyester, which offers the greatest clothing comfort and feels just like cotton. Conforming to the stringent requirements of the bluesign system, the range extends from antibacterial knitted shirt qualities with outstanding moisture management to more sturdy pant materials with 3XDRY bio-feelgood technology and very light windproof and waterproof 3-layer laminates, which ensure a high level of climate comfort thanks to the optimally breathable Sympatex membrane.

The “guaranteed green” Sympatex membrane is 100 percent recyclable, PTFE-free and PFC-free and climate neutral. It is absolutely environmentally friendly as well as skin-friendly. Moreover, it is certified in accordance with the strict environment standards. The water- and dirt-repelling properties are achieved exclusively through the use of the ecorepel Bio und 3XDRY Bio technologies, both based on renewable raw materials. Due to the exclusive use of polyester fibers, Inspire textiles are very durable, which further helps preserve resources. To top it all, their production requires significantly less water and energy.

CompaniesFairer Working Conditions: How It Works

CompaniesFairer Working Conditions: How It Works

- ISPO awards

- Mountain sports

- Bike

- Design

- Retail

- Fitness

- Health

- ISPO Job Market

- ISPO Munich

- ISPO Shanghai

- Running

- Brands

- Sustainability

- Olympia

- OutDoor

- Promotion

- Sports Business

- ISPO Textrends

- Triathlon

- Water sports

- Winter sports

- eSports

- SportsTech

- OutDoor by ISPO

- Heroes

- Transformation

- Sport Fashion

- Urban Culture

- Challenges of a CEO

- Trade fairs

- Sports

- Find the Balance

- Product reviews

- Newsletter Exclusive Area

- Magazine