To finally become more sustainable, the sportswear industry needs new, innovative materials that are highly functional and have less impact on our environment. Many new ideas have been developed in recent years, but no one has yet been able to find a satisfactory answer to a central problem facing the sports industry: What becomes of the product at the end of its useful life? How can a jacket be prevented from dissolving into microplastics in a landfill at the inevitable end of its life cycle and polluting our waters? With PrimaLoft® Bio™ Technology, PrimaLoft presents the first synthetic insulation and functional fabrics that are 100 percent recycled and biodegradable.

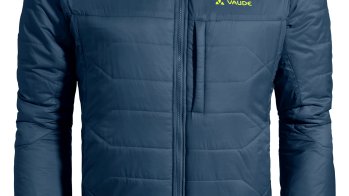

The first PrimaLoft® Bio™ products are scheduled to go on sale in fall 2020. Five major brand manufacturers have accompanied the development of PrimaLoft® Bio™ with their feedback and, as cooperation partners, will be among the first to include the new material in their collections: Helly Hansen, Houdini, L.L.Bean, Norrøna and Vaude. "We are working with a community of brands that share our common sustainability values and goals," says Mike Joyce, president and CEO of PrimaLoft. PrimaLoft will present the first prototypes of this collaboration at ISPO Munich 2019.

Of course, PrimaLoft® Bio™ continues to focus on the quality and long life of the fabrics. The longer a product can be used and does not need to be replaced due to wear and tear, the smaller its ecological footprint. Mike Joyce: "PrimaLoft® Bio™ is definitely not about encouraging the premature disposal of garments. Rather, we want to create a consistently responsible solution for the end of the product lifecycle." Brand partners expect the same. Philip Tavell, Category Managing Director, Ski/Mountain at Helly Hansen: "PrimaLoft® Bio™ allows us to continue our efforts in the area of sustainability further without compromising performance. It's a win-win situation for consumers and the environment."

First Prototypes and Insights into PrimaLoft's Fiber Production

"With the PrimaLoft® Bio™ project, we are looking for ways to make nature and technology work better together, instead of always having function at the expense of the other," Eva Karlsson, CEO of Houdini.

PrimaLoft® Bio™ fibers are made from 100 percent recycled material. Only a special further development of the synthetic fibers ensures that they can be biodegraded much faster. When PrimaLoft® Bio™ fibers come into permanent contact with naturally occurring microbes in landfills or the ocean, these microbes consume the fibers many times faster than conventional synthetic fibers. All that's left behind is water, methane, CO2 and biomass. Best of all, the technology has further potential for the entire textile industry.

To date, PrimaLoft has recycled more than 95 million plastic bottles into high-quality insulation fabrics. By 2020, 90 percent of PrimaLoft's insulation products will be made from at least 50 percent post-consumer recycled material without compromising performance. Next, PrimaLoft will work to further reduce its environmental footprint in the supply chain as well, with a focus on reducing energy consumption and CO2-emissions, as well as on the development of biodegradable products and the use of natural plant fibers.

- ISPO awards

- Mountain sports

- Bike

- Design

- Retail

- Fitness

- Health

- ISPO Job Market

- ISPO Munich

- ISPO Shanghai

- Running

- Brands

- Sustainability

- Olympia

- OutDoor

- Promotion

- Sports Business

- ISPO Textrends

- Triathlon

- Water sports

- Winter sports

- eSports

- SportsTech

- OutDoor by ISPO

- Heroes

- Transformation

- Sport Fashion

- Urban Culture

- Challenges of a CEO

- Trade fairs

- Sports

- Find the Balance

- Product reviews

- Newsletter Exclusive Area

- Magazine