Circularity is a hot topic when it comes to transitioning production methods and creating future-oriented, resource-conserving materials and products. It focuses on two circular systems: the biological cycle and the technical cycle. In the biological cycle, products are designed to be assimilated by nature. In the technical circularity, synthetic materials are recycled and reintegrated into the production cycle.

Prof. Dr. Michael Braungart, the founder of EPEA Hamburg, developed the "Cradle to Cradle" principle with William McDonough in the early '90s. Their aim then and now is to establish circular systems that are future-proof, allowing materials to become nutrients. The following eight examples showcase key players in the production and processing of natural materials, which can shift the needle towards more circularity.

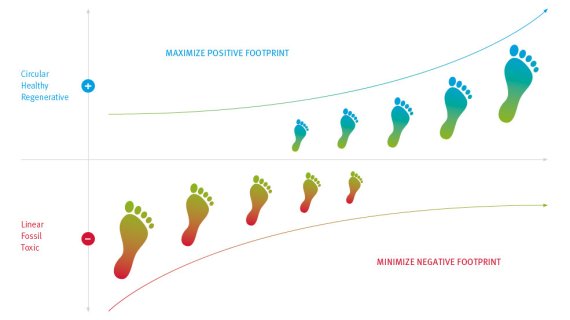

The creators of C2C: Those seeking an eco-efficient business model that adds quality value at every step, beneficial for the planet, should consider the “Cradle to Cradle” principle right from the product design stage. Epea enables companies and their supply chains to design and optimize products regarding material health and recyclability, ensuring they remain a resource for the future. For Epea, design is the initial signal of human intention, connecting performance with innovative and advantageous design. This approach ensures the production of items truly suited for our environment, fit for unlimited resource regeneration using healthy materials.

The demand for functional sustainability is increasing. Insulating clothing with Lavalan paves the way for more circular economy practices. It is made from pure wool and corn-based PLA fibers. This durable product has a long lifespan and can be easily recycled when the time comes. The natural breathability of wool, odor neutrality, moisture management, and temperature regulation have positive effects. Lavalan's natural insulation blend is versatile and offers high wearing comfort. Lavalan, made in Germany, exclusively uses European wool and upholds ethical farming practices and animal welfare. Other advantages include the biodegradability of wool, which, with proper processing, integrates into the biological cycle without residue.

The Südwolle Group and the ZQRX program by the New Zealand Merino Company demystify the journey from farm to yarn, emphasizing sustainability and innovation. With their supply chain expertise, the Südwolle Group provides insights into their production process and aids designers in understanding the effective application of their yarns and technologies. The collaboration with the ZQRX platform, a regenerative farming program with long-term goals and partnerships, stands out. ZQRX is an index for regenerative farming, helping farmers work in tandem with nature to consistently enhance outcomes for humans, animals, and the environment. Holistic, long-term partnerships are sought to supply global brands with innovative, top-quality yarns that, when properly used, can be reintroduced into the biological cycle.

In the realm of animal fibers, particularly within a complex global supply chain, transparency proves crucial. Founded in 1922, the Schneider Group boasts a rich history. The company aims to assist clients in sourcing, processing, and delivering natural, fully traceable products. As a family business, the Schneider Group possesses a globally certified network with operational centers on all continents. The company's Authentico label represents certified wool from highly committed sheep farms. The sheared wool is processed in the company's certified factories, guaranteeing a transparent and digitally traceable journey from farm to fiber.

Down insulation is trendy for producing outdoor and activewear. The many positive properties of this natural material are convincing, as highlighted by an independent Life Cycle Assessment study (LCA) of this natural material commissioned by the International Down and Feather Bureau (IDFB). The result: compared to synthetic fillings, down has 85 % to 97 % lesser environmental impacts. The findings span five categories: human health, ecosystems, resources, cumulative energy demand, and climate change. Besides, down offers excellent warmth with light weight. IDFB member down and feathers are ethically impeccable natural resources, which can be reused and biodegrade, if used properly.

In the realm of soft cellulose fibers, Lenzing is a pivotal player within the textile industry. The company is known for delivering high-performance, quality fabrics while emphasizing sustainable production practices. Their in-house brand, Tencel, represents Lyocell and Modal fibers that can seamlessly integrate into nature’s cycle and are fully traceable. These fibers come from renewable, certified wood sources and carry certifications for both compostability and biodegradability, ensuring they can fully reintegrate into nature.

Accessories like cable ties often end up in nature, contributing to the global influx of plastic, especially into oceans. Fibrestrap offers a transformative solution - a paper cable tie capable of replacing conventional plastic counterparts in all applications. Fibrestrap is made from Scandinavian wood fibers, is sturdy, recyclable, and biodegrades within a reasonable timeframe, reducing the CO2 footprint by 80 %. Only fossil-free energy is used in the production of Fibrestrap cable ties. The result: a circular, environmentally friendly alternative to plastic cable ties.

We’re increasingly becoming aware of microplastic pollution in our environment. However, recreational activities like snow sports and cycling broaden the environmental impacts, with chemical deposits also playing a role. Nzero addresses the issue. The company develops ski-waxes, which are made from 100 % bio-based materials and which can biodegrade in the environment. With 88 % plant-based ingredients, their bike-lubricants have the highest bio-based percentage on the market. Both products are certified with the stringent Eu Ecolabel. Nzero continuously researches to enhance the functionality and effectiveness of its winning formula.

- ISPO awards

- Mountain sports

- Bike

- Design

- Retail

- Fitness

- Health

- ISPO Job Market

- ISPO Munich

- ISPO Shanghai

- Running

- Brands

- Sustainability

- Olympia

- OutDoor

- Promotion

- Sports Business

- ISPO Textrends

- Triathlon

- Water sports

- Winter sports

- eSports

- SportsTech

- OutDoor by ISPO

- Heroes

- Transformation

- Sport Fashion

- Urban Culture

- Challenges of a CEO

- Trade fairs

- Sports

- Find the Balance

- Product reviews

- Newsletter Exclusive Area

- Magazine