Then find out how ISPO brings together all the players of the sports industry - brands, manufacturers, technology providers, material suppliers, scientists and consultants - and creates the space in which real sustainability solutions are created.

Speaking with Kutay Saritosun, Director of Brand Services and Partnerships, bluesign technologies, he believes the legislation will play an important role in eliminating greenwashing.

The Green Claims Directive is a proposed European Union regulation aiming to prevent "greenwashing" by setting clear, evidence-based requirements for environmental claims made by companies, ensuring consumers receive reliable information about product sustainability. While initially expected to come into force by 2027 or 2028, its future is currently uncertain due to recent developments at the end of June that saw it not withdrawn, but certainly delayed.

As for the Digital Product Passport, that is continuing on its path and expected to become valid in 2027. The DPP will include essential details such as a unique product identifier, compliance documentation, and information on substances of concern. It will also provide user manuals, safety instructions, and guidance on product disposal. By offering a detailed digital record of a product’s lifecycle, the DPP will enhance supply chain management, ensure regulatory compliance, and help companies identify and mitigate risks related to authenticity and environmental impact. Saritosun states

The DPP rolling out in the next two year, all the legislation opening up, that’s going to help combat greenwashing. QR codes into garment, regulatory information, supply chain, sustainability, certifications GRS, Bluesign, all off these claims on the garment and will tie into certification. This is definitely going to help with communication and transparency.

For anyone confused with the new legislation coming into play, you are not alone, as suppliers throughout the chain are doing their best to be transparent at all stages and be ready to move when it all becomes crystal clear. Saritosun adds

I know a lot of brands have started data for product lifecycle systems of the brands, they need to feed the data into system. A lot of brands are mapping their supply chain. They traditionally don’t have the visibility, they have tier 1 and the finished goods, with the DPP it dictates the supply chain. As a brand you need to know the supply chain partner, you need to put action forward.

This isn’t unique, brands in the past have worked in a very silo-driven setup and this cannot continue. On top of the DPP and data chasing, you then have the Corporate Sustainability Due Diligence Directive (CSDDD). It is a European Union directive that requires large companies to identify, assess, and address potential and actual negative impacts on human rights and the environment within their operations and value chains. This directive aims to ensure companies take proactive steps to prevent and mitigate harm, promoting more responsible and sustainable business practices. And if that wasn’t enough you have And on top of that report each year annual report.

One way of engaging a clear and honest approach is through certification, and the bluesign partners, textile mills who have been advised and reassessed in being accredited with clean chemistry processes and responsible production in the textile industry, this helps enormously. It offers reassurance and it isn’t a one hit wonder. Factories are visited annually, part of bluesign’s action plan with their partners in offering improvement that is beyond certification.

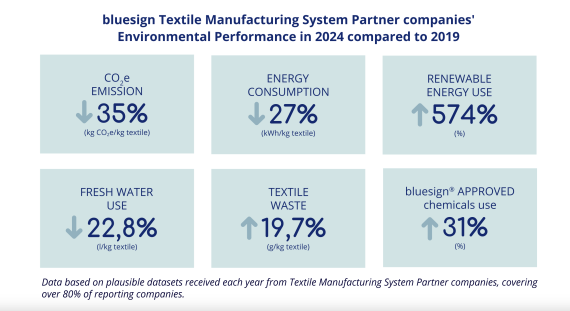

This rings true with the bluesign Impact Report published this July, with a clear overview that their System partners are positively contributing on an environmental level. In 2024 compared to 2019, carbon emissions are down 35%, energy and water use down too by a significant amount, and interesting renewable energy use up a staggering 574%. This is clear and valuable information that can be input into a brand’s supply chain’s data cache when sourcing bluesign approved fabrics.

One effective way to avoid accusations of greenwashing is to maintain tight control over the supply chain. Imbotex serves as a prime example of this approach. The Italian supplier of performance padding takes a hands-on method when developing its innovative products.

The latest offering from the company is ‘Le Jean Recycle’ denim pad, which emphasizes both performance and sustainability. Giada Bertinazzo, Sales at Imbotex, explains

We collect denim sourcing scraps and open the fibers through garnetting. We mechanically shred the denim into fibers, and then we combine it with our recycled low-melting polyester which is derived from certified ocean-bound plastic.

With its "Made in Italy" product range, Imbotex has established a European-based network that collaborates with shepherds in Germany, France, Bavaria, and Norway. This initiative delivers not just natural fibers but also a near-market solution. This near-shoring strategy helps dispel the myth that merino wool can only be sourced from the Southern Hemisphere. Wools are washed, combed and treated for washability with a chlorine-free treatment in North of Italy.

Bertinazzo also emphasized the importance of collaboration among brands. One notable project is the Rope to Insulation initiative developed in partnership with Mammut. She elaborates

They have a significant production of ropes, and climbing ropes must undergo extensive checks and pass several tests before they reach final quality control. We collect climbing rope production scraps and any ropes that do not pass quality checks.

This latest upcycled innovation was born out of Mammut Sports Group's request to find a way to reuse scraps from climbing rope production. The company's primary focus is on enhancing resource efficiency and durability while embracing a circular economy approach. The resulting product, Rope to Insulation padding, is made from polyester climbing rope production scraps sourced from the rope manufacturer Teufelberger and showcases Imbotex's expertise in upcycling. This innovative insulation material is derived from industrial rope production scraps. What makes it unique is its mechanical technology, which eliminates the need for chemical additives or water usage. Available in various weights, it has been tested by certified laboratories and has exceptional insulating properties, able to protect mountaineers from cold and harsh weather conditions.

Brand ingredients deliver an inherent transparency to the textile mills when sourcing yarns, but teaming up in partnerships gives that extra level of security. CiCLO, the textile additive that enhances synthetics through biodegradable solutions, how do they confirm that it is actually included in a batch. Alastair Drew, Business Development Europe & International Markets, CiCLO clarifies

CiCLO technology has an authentication program that requires every manufacturing batch of CiCLO fibre to be tested at a third-party laboratory to ensure that the correct percentage of CiCLO is present. A CiCLO Certificate of Authenticity (CCoA) is issued to the fibre manufacturer for each batch that is successfully tested. This certificate must accompany the fibers as they are passed down the supply chain. In addition, CiCLO has a garment hang tag program for the apparel and fashion industry.

REPREVE one of the world’s leading innovators in recycled and synthetic yarns, has launched REPREVE with CiCLO technology, recycled polyester and nylon embedded with a biodegradable technology that enables synthetics to break down naturally. REPREVE with CiCLO technology is enhanced with a patented additive at the fiber level that allows synthetic yarns to more closely mimic natural materials such as wool. This will enable them to break down in environments such as soil and seawater without compromising performance, durability, and dye-ability. These new offerings are designed to help tackle the environmental impact of microplastic fiber pollution from synthetic textile shedding.

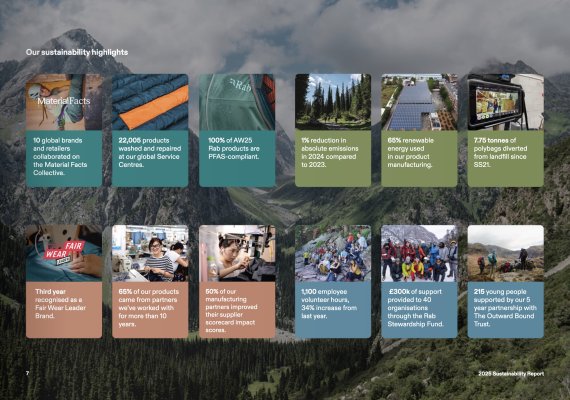

Equip Outdoor Technologies, the parent company of the technical outdoor apparel and equipment brands Rab and Lowe Alpine, has released its 2025 Sustainability Report. This marks the fifth year of reporting, during which Equip has made significant progress in each of its focus areas. By fostering open and collaborative relationships with supply partners, peers, and industry groups, the company has driven improvements throughout its supply chain.

The Material Facts Collective, led by Rab, demonstrated how collaboration among brands can enhance important initiatives. By adapting Rab’s original Material Facts tables and developing a methodology toolkit, overseen by the European Outdoor Group, any brand within the outdoor industry can now utilize these resources. Additionally, Equip has partnered with manufacturers to promote a transition to renewable energy, engaged its entire supply chain in efforts to phase out intentionally added PFAS by 2025, and achieved Fair Wear Leader status for the third consecutive year. Furthermore, the company has set records for employee volunteering hours.

Equip's activities align with a new five-year strategy launched in 2024 by incoming CEO Richard Leedham. This strategy, summarized in the company’s 2025 Sustainability Report, emphasizes a commitment to achieving market-leading environmental, social, and governance (ESG) standards as well as corporate social responsibility (CSR) initiatives.

The Material Facts Collective, consisting of a group of global outdoor brands has launched a toolkit for accurate product sustainability claims based on Rab’s Material Facts methodology. This toolkit includes input from notable brands and retailers across the UK, Europe, the USA, and Canada, such as Exped, Go Outdoors, Oberalp Group, and Tiso.

The methodology, first introduced by British brand Rab in October 2023, allows for standardized product data to be shared transparently with consumers and retailers, supporting responsible sourcing and compliance with upcoming ESG legislation. Material Facts provides essential sustainability data at the point of sale, including recycled content percentage, PFAS status, and country of manufacture. Future criteria may include material type, certifications, and durability.

Launched in September 2024 with support from the European Outdoor Group, the Collective aims to standardize sustainability data across the industry. The methodology has been tested by brands across apparel and hard goods to ensure scalability and robustness. Joanna O’Flynn, Corporate Social Responsibility (CSR) Manager at Tiso Group, confirms

A simple data table in a standard format, backed by a clear and tested methodology, is becoming essential. This enables us to share data with our consumers and ensures that we are collaborating with brands committed to effectively communicating sustainability metrics. Participating in the working group has allowed me to voice retailers' needs as we shape the communication, methodology, and outputs of the Material Facts Collective.

By keeping it simple, brands could eliminate multiple components, offer heightened transparency and deliver on circularity. Renowned outdoors creative director/senior Thomas Häkansonn has done just that with the launch of BelowTen, launched at Pitti Uomo. One yarn, one fabric (10NYL), one filling, four products in three colors with a clear focus on relevant garments. BelowTen does not define a look, instead BelowTen takes an holistic approach to product development, with a strong emphasis on sustainability, collaboration with manufacturing partners, and engaging directly with retailers and consumers to educate and build meaningful connections. Häkansonn explains

By using one fabric, obviously, that really cuts out a lot of hassle from sourcing multiple ingredients for a product. And I love this low-key, but this ironically is hard to find sometimes either from outdoor brands, but then they tend to be very outdoorsy. And I think that, so I was looking to have this kind of functionality, but making it more sartorial, working a lot with the fitting. So it's more like not so outdoorsy and the fit is more sophisticated.

Communication and sharing information is crucial to enable full transparency, and once again people are interested at all stages of the supply chain on what is happening before their tier and what is planned after. Häkansonn recommends

I think we should be more transparent about the processes, how we talk about sustainability, this is how we work with the fabrics, because people they are very eager to know. And I think that that is a good way to create, of course, if you don't present the relevance of sustainability to the retailer, if they think it's all about because a lot of brands have made it's all about money, how would they no one wants to pay.

And by passing the information to the retailer they in turn can communicated with the consumer. Häkansonn adds

It has to be an interaction, because the consumer, if it's presented in a good way to the consumer, the consumer will also understand the relevance, but if it's not, no one really knows what is the difference and why are we choosing sustainability.

Sustainability thrives through collaboration, communication and community. ISPO 2025 will bring these values to life. In the Sustainability Solutions Area, collaboration and the exchange of ideas will be central, demonstrating how sustainability is shaping the sports industry into a even more forward-thinking, responsible sector. Be part of it - from 30 NOV. – 02 DEC. in Munich.

Learn More

- End of Greenwashing: The European Digital Product Passport (DPP) will help combat greenwashing by ensuring transparency in product sourcing, lifecycle, and environmental impact, promoting trust in sustainability claims.

- Supply Chain Transparency: Brands need to map their supply chains and integrate clear, verifiable data into systems to comply with the upcoming regulations and avoid greenwashing.

- Collaboration is Crucial: Collaborative efforts like Material Facts Collective and initiatives such as Rope to Insulation highlight the power of working together to drive sustainability and improve resource efficiency across the industry.

- Certification Matters: Leveraging sustainability certifications like bluesign and GRS ensures credibility and reassures consumers about responsible sourcing and production practices.

- Clear Communication with Consumers: Open, transparent communication is essential. Brands must clearly convey their sustainability efforts to consumers, with retailers playing a key role in educating the end customer.

- ISPO awards

- Mountain sports

- Bike

- Design

- Retail

- Fitness

- Health

- ISPO Job Market

- ISPO Munich

- ISPO Shanghai

- Running

- Brands

- Sustainability

- Olympia

- OutDoor

- Promotion

- Sports Business

- ISPO Textrends

- Triathlon

- Water sports

- Winter sports

- eSports

- SportsTech

- OutDoor by ISPO

- Heroes

- Transformation

- Sport Fashion

- Urban Culture

- Challenges of a CEO

- Trade fairs

- Sports

- Find the Balance

- Product reviews

- Newsletter Exclusive Area

- Magazine