Innovations are the driving factor in the sports market. They arouse desires amongst consumers and thus warrant higher sales prices. In recent years, many innovations came from the fabrics sector. They have become increasingly lighter, more breathable and more elastic, and some people believe that no more features can be achieved. But far from it.

This time the ideas do not come from the textile industry, but from the electronics industry. In the future, flexible and printed electronics will be able to integrate many more capabilities in relation to materials than has ever been possible before. Experts agree that in the years ahead, they will occupy many more fields of application: from the supply chain to retail, all the way to equipment and clothing.

The process is slow, and this is due to the industries having limited contact with each other. Johannes Becker, Director of the PrintTronic Competence Center, part of the Schreiner Group, specializes in printed electronics. At the ISPO Digitize Summit he spoke about new areas of application and sought an open dialogue with the sports sector.

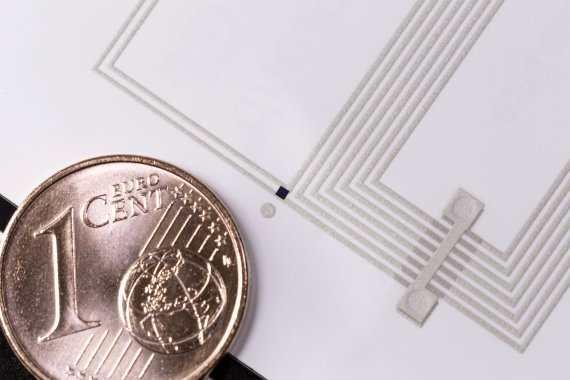

Printed electronics indicate the combination of conductive materials with paint and color systems, which are transferred extensively and cheaply onto foil, paper and other carriers such as certain textiles, in a number of layers. “Flexibility depends on the carrier material: the more flexible it is, the more flexible the whole electronic element will be,” explains Johannes Becker.

The printing is carried out using the long-established printing technique, which keeps costs under control. This imprinted conductive “color” undertakes the tasks of conventional electronics. It can conduct electricity and do other things that are of great interest in the sporting field: It can serve as a heating element, a reflector, an antenna, a user interface for connected electronic devices, and as a sensor for a wide range of measurements.

ISPO Digitize at the ISPO Munich 2018 in pictures

Many companies are currently considering how they can improve communications between their brand and their consumers. The product is an interface that, by means of integrated NFC (Near Field Communication) technology and an app on consumers’ smartphones, can establish a connection and display content. Until now, companies have primarily considered NFC labels, which are already being printed, and are flexible, washable, and skin-friendly.

However, other equally effective options include badges and patches, integrated pattern pieces or other accessories, which are attached to clothes and become part of the design. “However, you must understand that NFC technology can only be one part of the whole eco-system,” explains Becker. “First of all, you have to consider what information you want to display through the product and how you can succeed in getting the customer to use it repeatedly for communication.”

“Everything that is measurable in the form of chemical processes can be effectively displayed through printed electronics,” explains Becker. Sensors can analyze the athlete’s sweat and monitor their health. It is also possible to measure temperature and humidity. Temperature management systems could activate the integrated heating function, which also operates via printed electronics.

The 2018 Winter Olympic Games was the first commercial example of this. The American team wore Ralph Lauren coats that were equipped with heating elements in the coat lining. These jackets did not have sensors. The limited-edition jacket, priced at US$2,495, sold out in just a few days.

It is also possible to measure pressure points, for example to identify whether a shoe fits or not or, on a higher level of sophistication, to determine whether the shock absorption of a shoe is worn and a new purchase would be advisable.

The technology is being taken even further. Clothes can become credit cards, as they identify the wearer. “Imagine, for example, that a certain football jersey could allow you to access a selected area,” explains Becker. The products identify their wearers and can generate information about their whereabouts and activities. Clothes manufacturers could find out how their products are actually used, e.g. whether the trainers are worn for sport or for everyday use.

Safety aspects also come into this, be that the user’s safety or product protection (e.g. identifying stolen goods or black market products).

Additional fields of application appear when you consider the supply chain and the route the product travels before it is sold. Technology can be used to trace the movements of any item in store. The retailer sees which products are tried on again and again but never sold: the shoes may appeal to many, but they never fit.

Integrated RFID (Radio Frequency Identification) chips, which are also printed and are identified via electromagnetic waves, can provide information about where each product is during the production process. Becker: “Every time a product is scanned, data is collected and the product and its location are linked.”

You can therefore draw conclusions about the progress of production, which helps with identifying mistakes when recalling products.

Integrierte RFID (Radio Frequency IDentification)-Chips, die ebenfalls gedruckt und über elektromagnetische Wellen identifiziert werden, können in der Produktion darüber Auskunft geben, wo sich welches Produkt befindet. Becker: „Immer wenn ein Produkt gescannt wird, werden Daten erhoben, Produkt und Ort miteinander kombiniert.“

Daraus lassen sich Rückschlüsse über den Fortschritt der Produktion ziehen, die etwa beim Rückruf von Produkten dabei helfen, den Fehler genau zu lokalisieren.

SportsTechUnlocking the Future of Sports with AI

SportsTechUnlocking the Future of Sports with AI

- ISPO awards

- Mountain sports

- Bike

- Design

- Retail

- Fitness

- Health

- ISPO Job Market

- ISPO Munich

- ISPO Shanghai

- Running

- Brands

- Sustainability

- Olympia

- OutDoor

- Promotion

- Sports Business

- ISPO Textrends

- Triathlon

- Water sports

- Winter sports

- eSports

- SportsTech

- OutDoor by ISPO

- Heroes

- Transformation

- Sport Fashion

- Urban Culture

- Challenges of a CEO

- Trade fairs

- Sports

- Find the Balance

- Product reviews

- Newsletter Exclusive Area

- Magazine