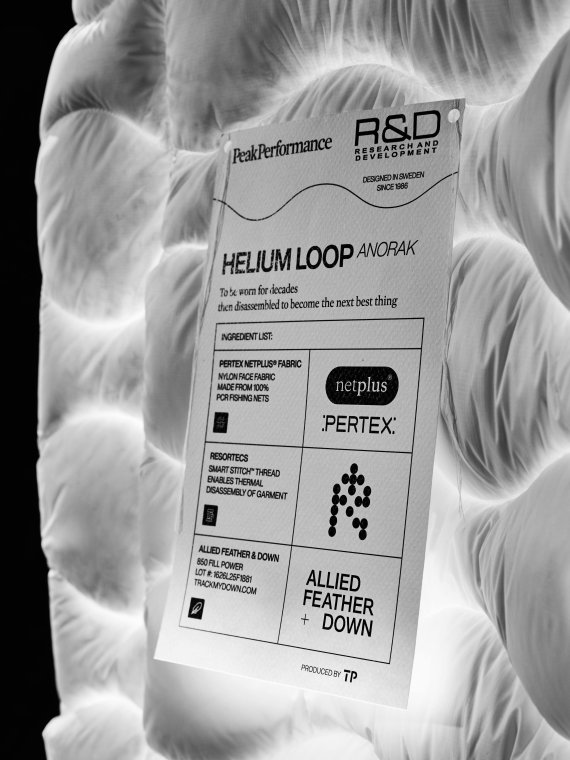

With the R&D Helium Loop Anorak, Peak Performance takes an innovative approach to the recyclability of down clothing by designing the anorak to be easily disassembled and the materials to be recycled. The company draws on the expertise of leading innovation partners from different stages of the value chain to achieve this, demonstrating how high performance, sustainability, and the circular economy can be harmoniously combined in a single product.

The R&D Helium Loop stands for “invisible complexity.” Peak Performance understands this to mean sophisticated technology hidden behind a deceptively simple aesthetic. Building on the iconic Helium quilting pattern, everything superfluous has been removed from the design to reveal the essentials: fabric, thread, and down. Clean lines and minimal details highlight the natural properties of each component, thereby optimizing recyclability.

Based on this design approach, Peak Performance has brought together various partner companies from the global supply chain. NetPlus is the fabric used in the product. NetPlus is fishing net waste, rescued by Bureo before it pollutes the ocean, re-engineered into 100 percent PCR nylon yarn. NetPlus yarn is then woven by Pertex to create the shell and liner.

The insulation is made of 100 percent RDS-certified down with 850 fill power from down specialist ALLIED Feather + Down. ALLIED Feather + Down specializes in hyper traceability and responsible sourcing in a global supply chain and processes material with low impact detergents in recycled water to achieve industry leading down quality and cleanliness.

To separate the components from each other at the end of the product's life, Peak Performance uses the innovative SmartStitch™ yarn from Resortecs. Manufactured in Europe, the yarn consists of polymers that react to heat and melt at a precisely defined temperature without damaging other materials. This allows the components to be separated and recycled. Final assembly is carried out by Peak Performance's production partner, TP Inc., creating a traceable cycle from discarded nets back to high-quality outerwear.

By reusing materials, the anorak significantly reduces CO₂ emissions and saves valuable resources. In addition, it is PFAS-free.

- Innovative design for true circularity

- Use of post-consumer recycled nylon (Pertex Quantum made from NetPlus)

- Use of heat-activated SmartStitch™ sewing thread from Resortecs for automated, non-destructive disassembly

- ISPO awards

- Mountain sports

- Bike

- Design

- Retail

- Fitness

- Health

- ISPO Job Market

- ISPO Munich

- ISPO Shanghai

- Running

- Brands

- Sustainability

- Olympia

- OutDoor

- Promotion

- Sports Business

- ISPO Textrends

- Triathlon

- Water sports

- Winter sports

- eSports

- SportsTech

- OutDoor by ISPO

- Heroes

- Transformation

- Sport Fashion

- Urban Culture

- Challenges of a CEO

- Trade fairs

- Sports

- Find the Balance

- Product reviews

- Newsletter Exclusive Area

- Magazine